Features

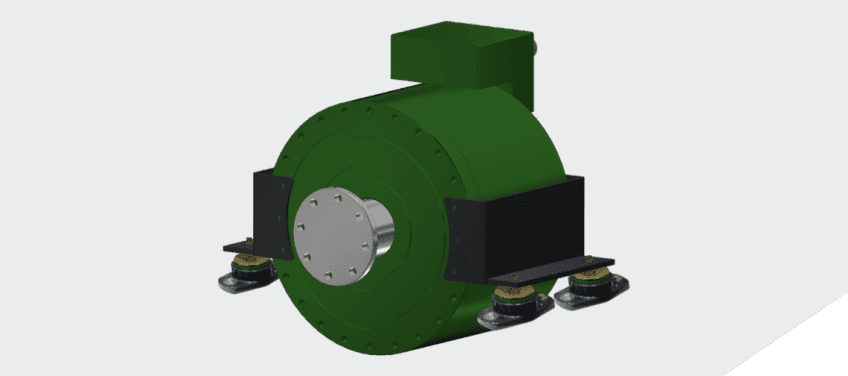

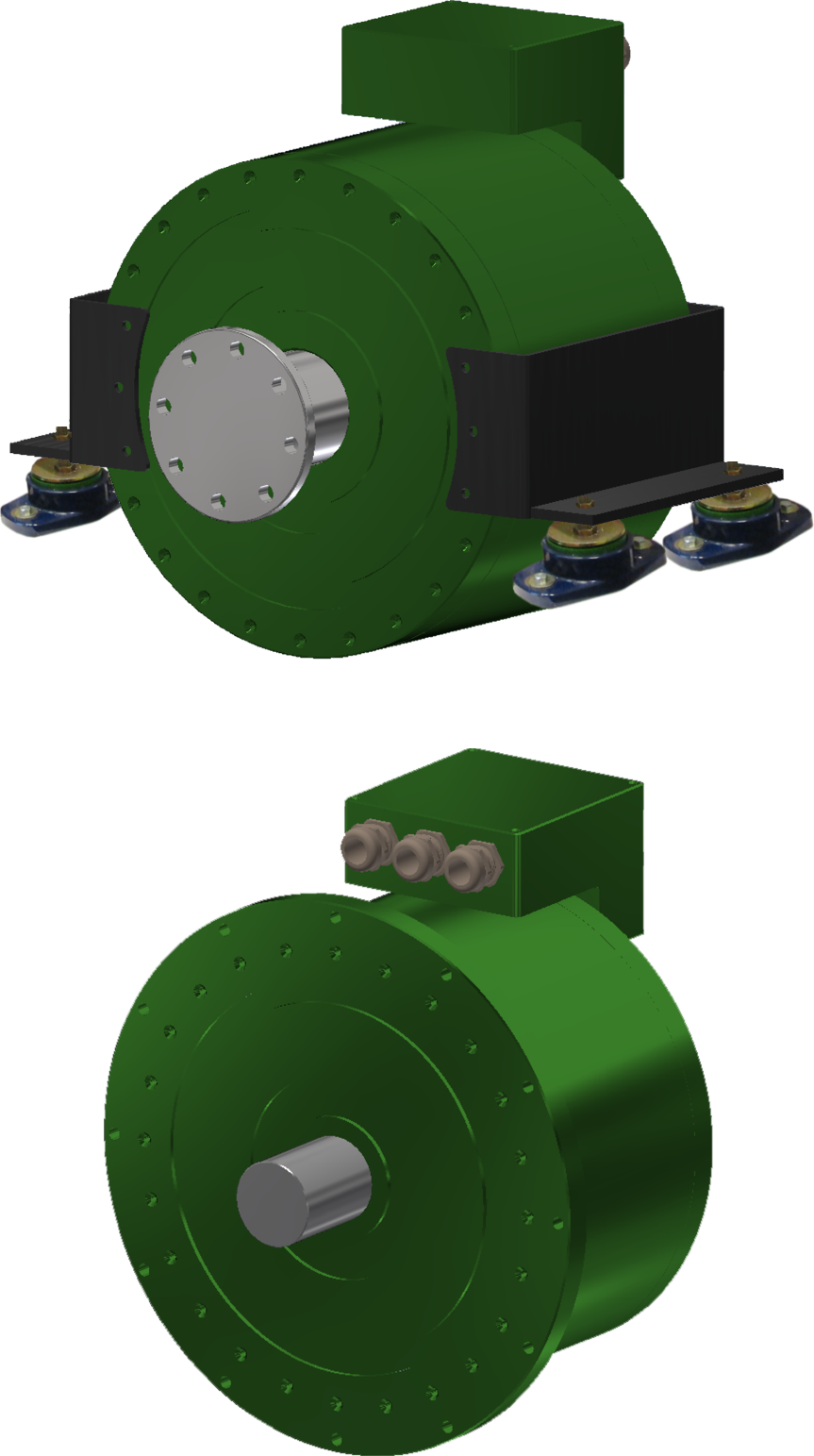

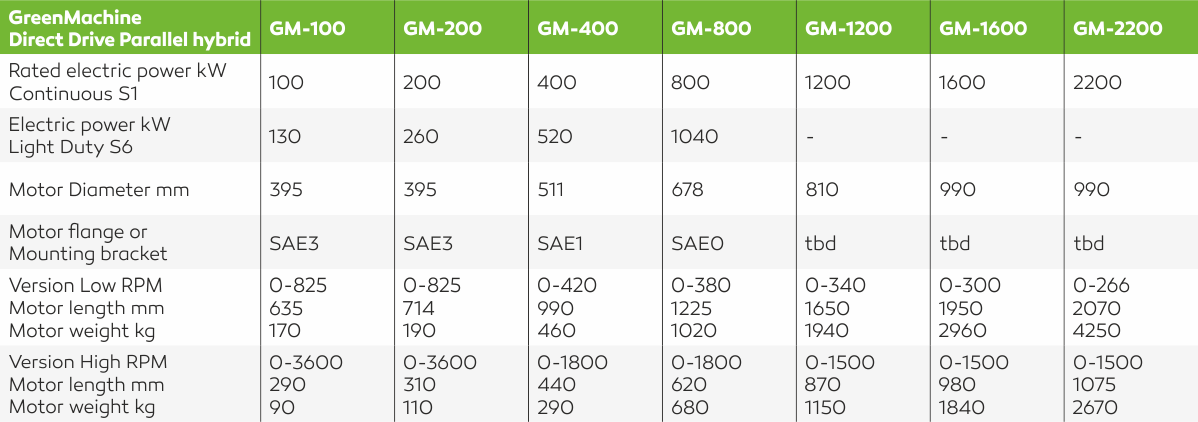

GreenMachine is a highly efficient permanent magnet electrical machine for propulsion and electric power generation. Low speed versions of GreenMachine are available for direct mounting to a propeller shaft without gearboxes. Medium and high speed versions are available for connecting to third party thrusters and gearboxes (parallel hybrid). GreenPower consists of a variable speed combustion engine connected to a GreenMachine acting as electric generator. In this way a highly efficient and light weight electric power generator plant is realized to further support a green environment.

GreenMachine and GreenPower

GreenMachine is a highly efficient permanent magnet electrical macine for propulsion and electric power generation. GreenMachine is available in RPM ranges in between 266 (low speed direct drive of propeller shaft) and 3600 (high speed generator set). GreenMachine can be either flange or bracket mounted. In addition, customer can choose between hollow shaft or solid shaft on one side or on both sides of the machine. In case of parallel hybrid applications, the low speed

GreenMachine can be connected to the propeller shaft on one side and the other side can be connected to the output shaft of gearbox.

GreenPower is built-up with a light weight and high speed diesel engine connected directly to a highly efficient GreenMachine electric generator. In this way a very compact and efficient generator set is realized. GreenPower can be built-up with diesel engines from Hyundai, Volvo, Steyr and Cummins. Flange mounting connections, vibration damping plates and other specifications can easily be adapted to accommodate other combustion engines.

GreenMachine and GreenPower are cooled by water cooling (50% water/50% glycol). Each GreenMachine and GreenPower is controlled by a GreenInverter which is connected to DC Bus of nominal 832VDC.

Advantages of electric propulsion

There are two main reasons to change to electric propulsion: zero emissions during electric propulsion and fuel efficiency. Fuel efficiency can be increased with electric propulsion when there is a large difference in operating hours at e.g. cruise speed and maximum speed (or power). The reason for this is that the combustion engine is running only at optimal efficiency when fully loaded; at all other operating points efficiency drops. Electric propulsion when combined with combustion engines realizes that the combustion engine is running at optimal efficiency most of the time, by using the spare power for charging battery packs and/or by switching off one or more combustion engines depending on load requirement. In addition, electric motor propulsion, especially when combined with steerable thrusters, gives a much better maneuverability when compared to combustion propelled vessels as the RPM can be easily controlled from zero to maximum. Some ship applications also require strongly reduced noise emission and this can be realized with the GreenPod steerable thruster as the electric motor is mounted ‘under water’ for optimum noise reduction.

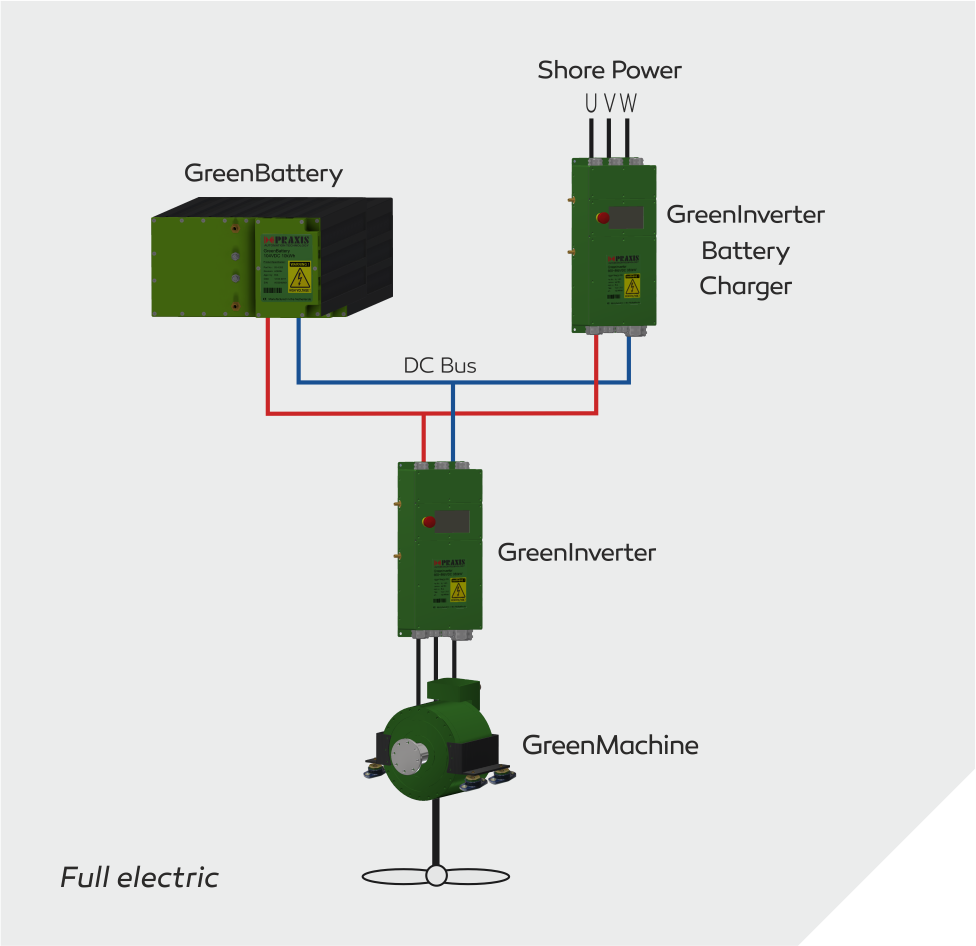

Full electric propulsion

The full electric propulsion uses an electric motor to drive the propeller shaft. Electric power is coming from battery banks and charging is done through shore power. Combustion engines are not installed. With large batteries you can have long periods of electric propulsion and the AC grid for hotel load is generated from the battery bank too. The highly efficient GreenPod steerable thruster perfectly fits into full electric applications.

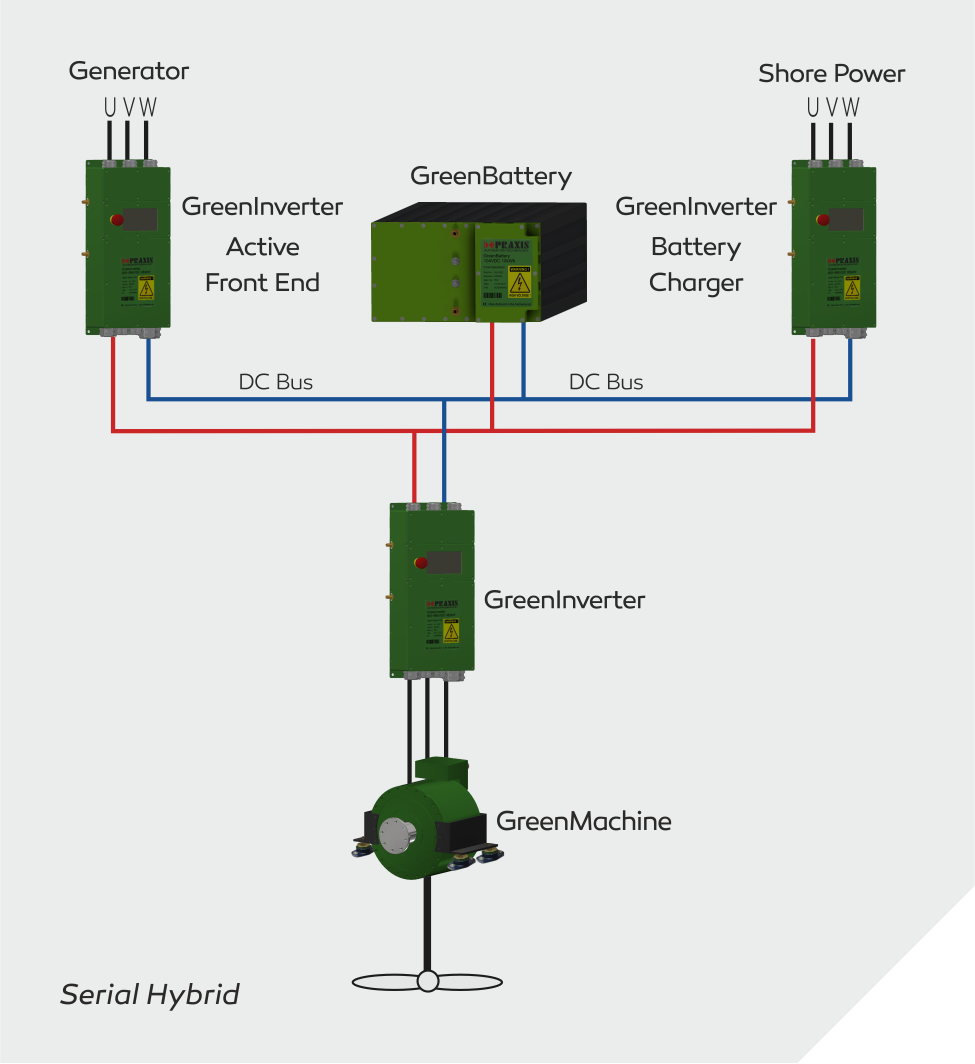

Serial hybrid propulsion

The serial hybrid also uses an electric motor to drive the propeller shaft. Electric power is coming from battery banks or, when battery bank is empty, from a combustion generator set. Charging of the battery bank is done through the combustion generator set or by shore charging. With large batteries you can have long periods of electric propulsion without the need for combustion engines to run as the AC grid for hotel load is generated from the battery bank too. The highly efficient GreenPod steerable thruster perfectly fits into full electric applications.

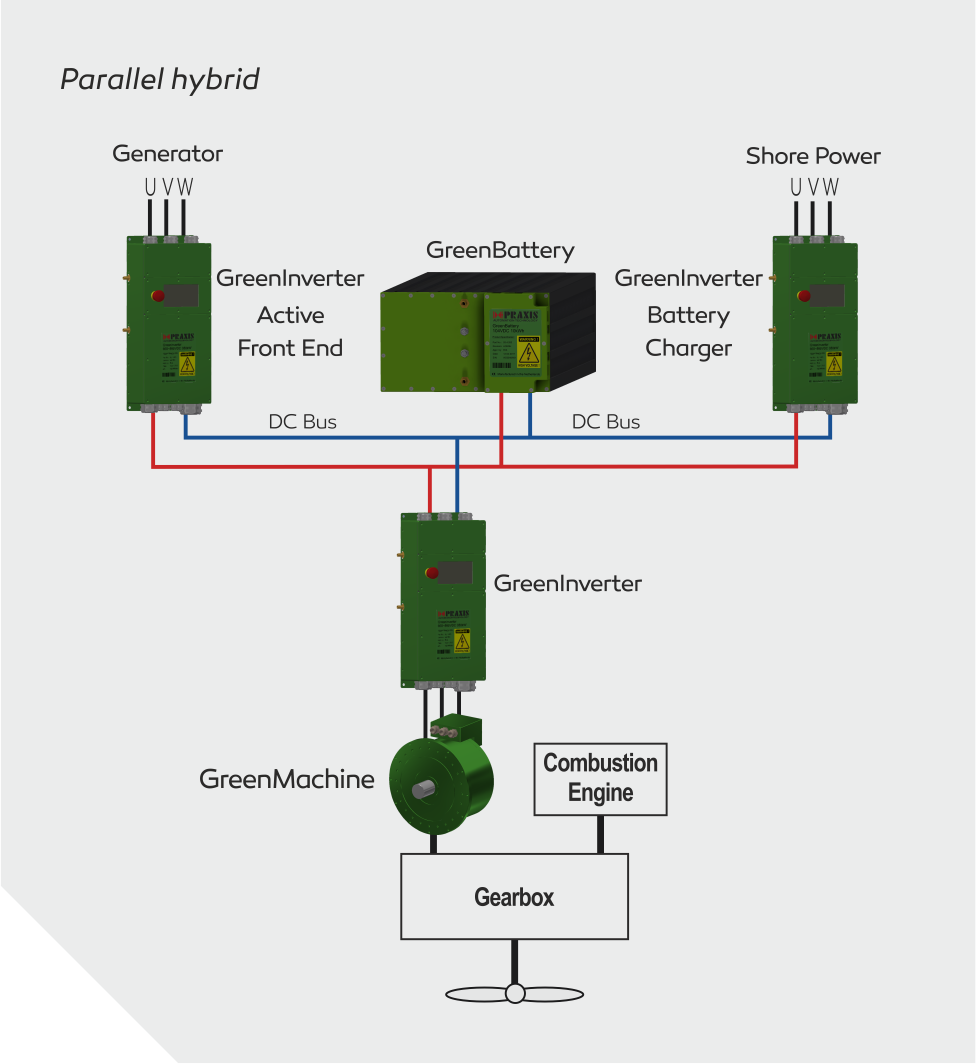

Parallel hybrid propulsion

The parallel hybrid propulsion system uses both a combustion engine and an electric motor to drive the propeller shaft. In fact, the combustion engine and the electric motor are mounted in parallel.

Parallel mounting is generally done in one of two ways:

- The propeller shaft from the combustion engine is split in two parts and the electric motor is mounted in between the two shaft parts. This means that the electric motor is mounted in-line with the propeller shaft. The electric motor has also to carry the usually much higher load from the combustion engine.

- The highly efficient permanent magnet electric motor with hollow shaft fits this purpose. The electric motor is mounted on an additional input of the gear box which is mounted in between the combustion engine and the propeller shaft.

for charging the battery banks.

In case there is a big difference in between operating hours at cruising speed compared with operating hours at maximum speed/power it makes sense to install a parallel hybrid system. The relatively small electric motor can propel the vessel at cruise speed for longer periods. When maximum speed/power is required, the large combustion engine takes over the propulsion and the electric motor is used as generator for charging the batteries. The parallel hybrid has built-in redundancy as the shaft can be driven by either the electric motor or the combustion engine. The highly efficient GreenMachine perfectly fits into parallel hybrid applications.

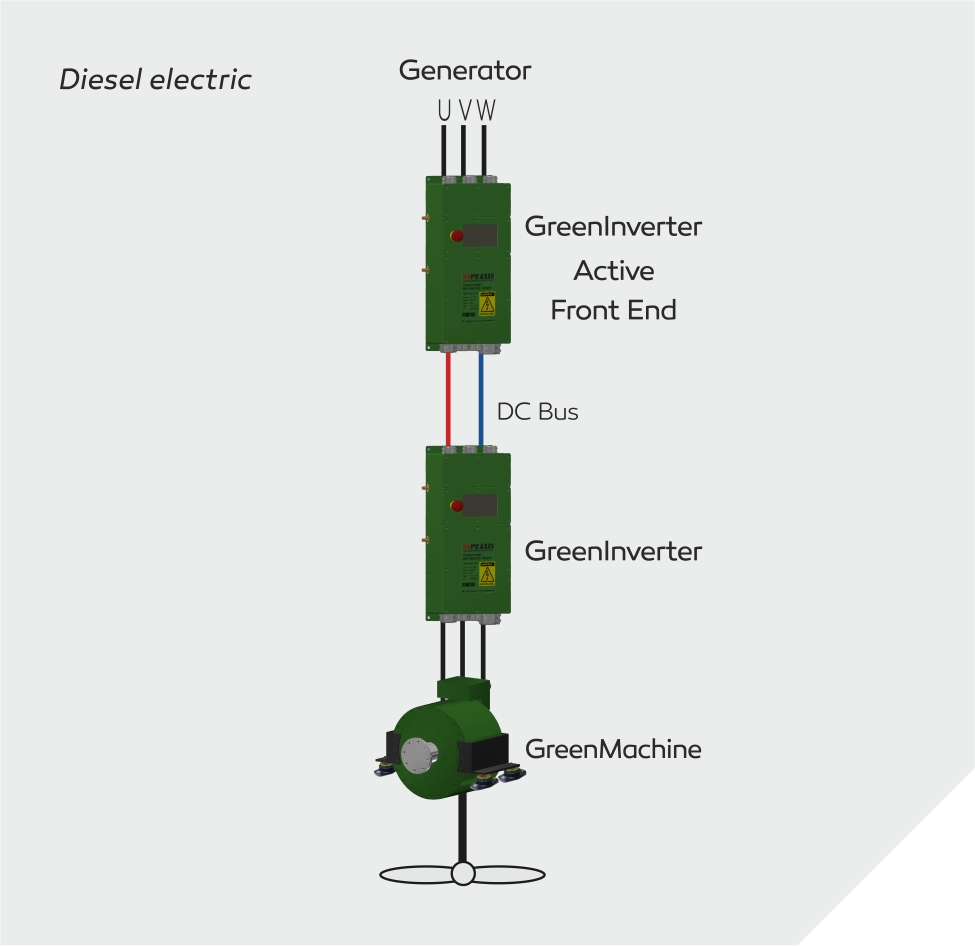

Diesel-electric propulsion

A diesel-electric propulsion system uses generator sets to generate electric power for the electric propulsion motors. The generator sets consist of a combustion engine, which could be gas or diesel, and is connected directly to an electrical generator. The electric propulsion motor is connected directly to the propeller shaft. The diesel electric system usually has multiple generator sets and multiple electric motors connected to a common electrical DC bus. The highly efficient GreenPod steerable thruster and the GreenMachine electric generator fit perfectly into diesel-electric applications. Note that there is no electric storage of energy in a diesel electric propulsion application.