Power Management System

The Mega-Guard Power Management System (PMS) is an advanced system for full automation of power plants

Features

The Mega-Guard Power Management System (PMS) is an advanced system for full automation of power plant, including power management, diesel engine control, generator control, synchronizing, generator protection and optional diesel engine safety system. Each generator set is equipped with its own independent and autonomous PMS system. This ensures the highest degree of reliability and availability. The Mega-Guard PMS is supplied as a complete product and no additional components are needed for automation of a low voltage switchboard up to 690VAC.

The Mega-Guard PMS is operated through a user friendly touchscreen (5,7″ or 8″) for intuitive operation and monitoring of power plant.

Reliable operation is guaranteed by 6 operator pushbuttons for essential functions. All essential power plant parameters are displayed on the touchscreen. The touchscreen supports swiping in between pages and activating sub menus with the touch of a finger.

Mega-Guard PMS is built-up with the following three items for each generator:

- PMS Operator Panel for flush panel mounting in switchboard

- PMS Controller for DIN rail mounting inside switchboard

- I/O Cable interconnecting the PMS Operator Panel and the PMS Controller

Both the PMS Operator Panel and the PMS Controller are equipped with a powerful ARM microprocessor for independent function execution.

Application

The Mega-Guard PMS can be configured for a mixture of the following applications:

- diesel generator

- shaft generator

- automatic bus tie breaker

- emergency generator

- shore connection

Mega-Guard PMS provides for auto starting, synchronisation and load sharing functions. Metering functions include 3 phase voltage, current, frequency and power measurement, calculation of power factor and running hours. Diesel engine, generator and circuit breaker are controlled and monitored by Mega-Guard PMS. Safety functions are executed in accordance with the applicable ANSI standard (see PMS protection function table).

Other functions include black-out start, consumer enable when enough power and preferent tripping in case not enough power available.

Mega-Guard PMS includes a PLC programming option and graphic editor which is not needed for most switchboard applications. Special applications can be programmed with the built-in and optional

PLC logic. The PLC logic is in accordance with the IEC61131 standard.

Mega-Guard PMS can be extended with additional modules to realize following functions:

- Safety system for diesel engine

- Differential tripping

- Check synchronizer with back-up

- measurement of kW, V, A, Hz and Cos φ

- Analog control for frequency and voltage

- Additional Controllers for user

- functionality (requires PLC programming (option)

Installation and commissioning of Mega-Guard PMS can be executed by switchboard builder and does not require special skills. The technician can easily set switchboard and power plant parameters in the Mega-Guard PMS with the user friendly PMS Operator Panel with touchscreen. Parameters such as generator power, number of generators, bus tie breaker, busbar nominal voltage, alarm limits, type of generator etc. can easily be entered in the menu driven operator interface.

PMS Operator Panel

The PMS Operator Panel is supplied in a compact DIN compatible housing for flush panel mounting in switchboard.

The PMS Operator Panel is equipped with a user friendly touchscreen and a powerful ARM microprocessor which executes the power management functions and optional PLC logic.

The PMS Operator Panel is available in three versions for the following market segments:

- Commercial ships : 5.7” touchscreen and metal frame with 6 pushbuttons

- Mega yachts : 5.7” touchscreen with full glass front

- Navy ships : 8” touchscreen and metal frame with 6 pushbuttons

The colour touch screen continuously displays metering values (kW, Hz, V, A, pf, kVAr), circuit breaker status, standby generator number and alarms. Operator mode selection can be executed with pushbuttons or the touchscreen. The rear side of the PMS Operator Panel is equipped with detachable terminal strips, four Ethernet ports and a USB port. Communication between Mega-Guard PMS systems takes place via Ethernet wired in a loop and occupies two Ethernet ports on each PMS Operator Panel. The two remaining Ethernet ports can be used for connection to e.g. an external monitoring system and/or to the diesel engine. RS485 and CAN bus communication are supported as well. The USB port is used for a memory stick to upload or download an application program. Terminal strips are available to connect the 24VDC power supply and a number of inputs and outputs. The switchboard can be configured in such a way that installation of separate gauges is not required with Mega-Guard PMS.

PMS Controller

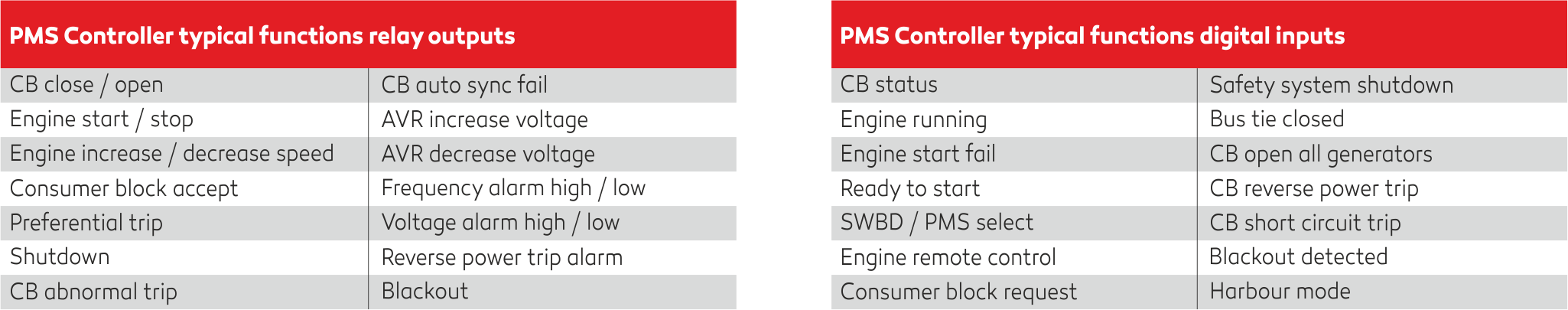

The PMS Controller is installed on a TS35 DIN rail inside main switchboard at each generator section. I/O signals from generator, busbar, circuit breaker and engine are directly connected to this Controller. The PMS Controller is equipped with a powerful ARM microprocessor executing metering, safety and generator control functions. The PMS Controller can also be delivered as an independent check synchronizer.

The PMS Controller has the following inputs and outputs:

- 3 phase busbar voltage (0~690VAC)

- 3 phase generator voltage (0~690VAC)

- 3 phase generator current (0~5A)

- 14 relay outputs

- 14 digital inputs

The PMS Controller is connected to the PMS Operator Panel via an I/O Cable. The I/O Cable is standard available in two lengths: 3m and 5m.

PMS Configuration

- main settings

- start/stop

- auto start/stop

- alarm limits

- CB open/close

- consumer

- I/O

- load sharing

- preferential group

A back-up of the configuration can be made on an external PC or on a USB stick connected to the USB port.